Technology

Use of 3D Printing in Injection Molding

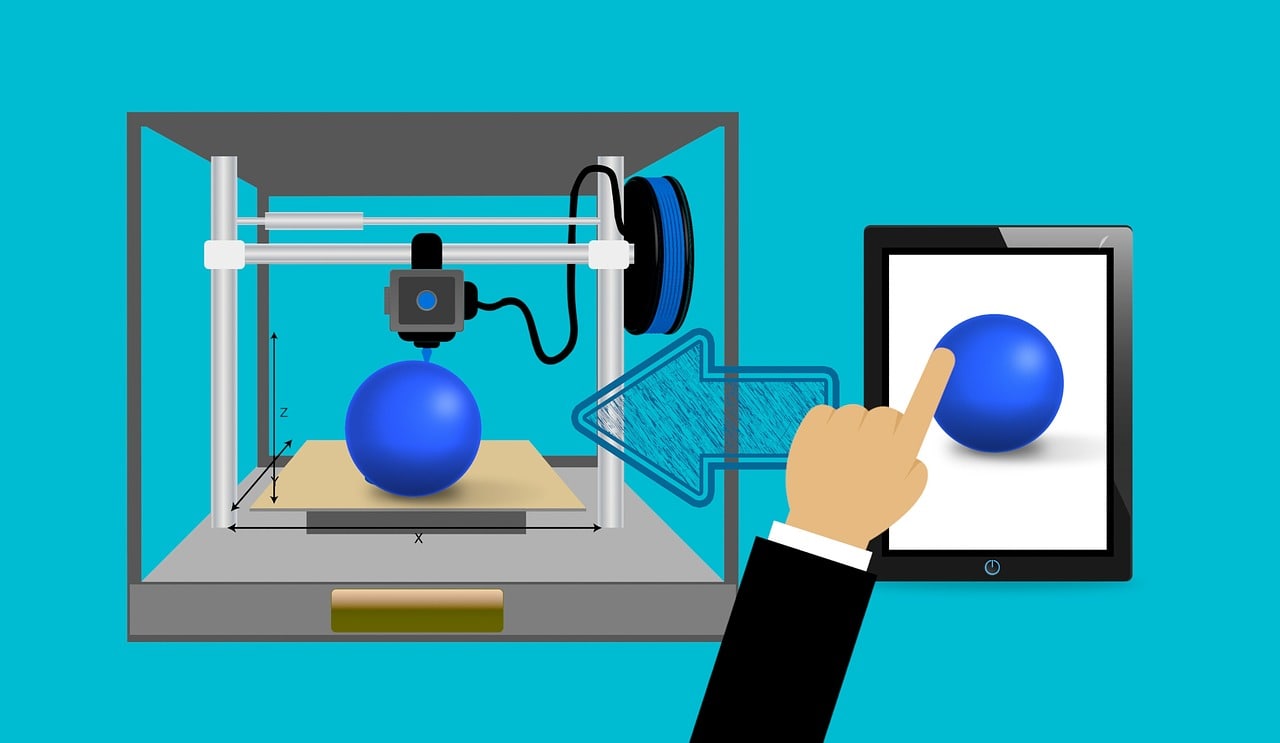

Use of 3D Printing in Injection moulding, Injection moulding is a 3d printing manufacturing process for 3d objects by injecting molten material into a mould

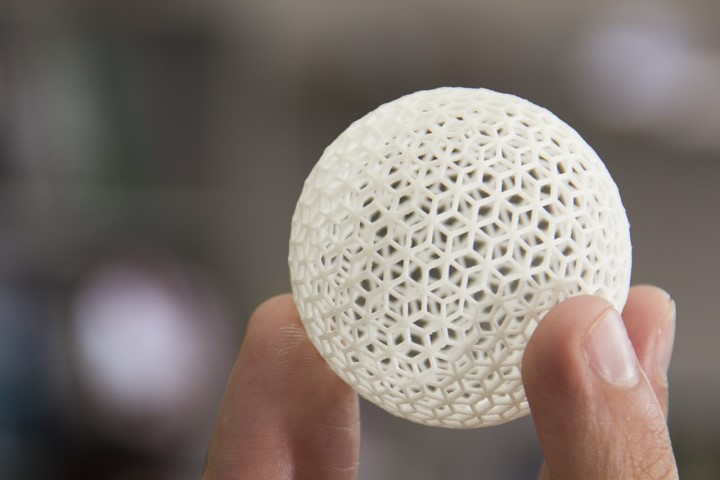

The recent years have seen 3D printing to become extremely useful in manufacturing. This is most specifically true in plastic injection moulding. The companies make use of a 3D printer to create a specific part from a model, concept plastic art and drawing. It can take 20 minutes to 48 hours depending on the complexity and size. In most cases, you are able to get hold of a finished replica of your part in just about a matter of a few hours. Hire reliable cheap injection moulding services.

One of the major developments to have taken place today in the field of 3D printing is its ability to print a plastic injection mould. Today the 3D molding technology need not have narrow part tolerances needed to make a plastic injection mold which can withstand extremely high volume. Once the part tolerances are solved, the mold making will surely become a viable option that will have a number of benefits.

1. Are 3D printing and injection moulding complementary of each other?

3D printing and injection moulding are not competing for technologies as much as they are complementary. They can be used theoretically used for manufacturing and can also be used technically for rapid prototype generation. The trend for the processes of additive manufacturing is growing with the rising time. The most serious kind of manufacturing is performed with injection mouldingequipment. In most cases, a 3D printer is an effective tool for the development of the rapid prototype.

Injection moulding is one of the most common methods for mass producing parts of plastic. This is specifically ideal for producing large numbers of identical parts having tight tolerances. The past had witnessed 3D designing in the manufacturing and design process to create and also verify prototypes which would be injection molded later.

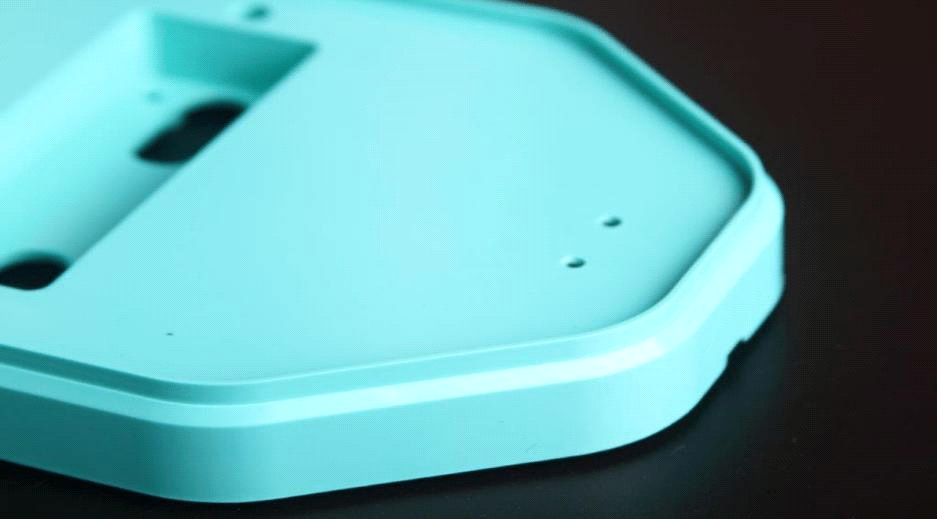

Injection moulding is a highly demanding application for 3D printed material and the molds need to withstand the forces at a high temperature while retaining the dimensional accuracy. The 3D printing in injection molds are suited for the following:

- » Fast turnaround times

- » Mold designs wherein iterations and changes are probably

- » Low production quality applications

- » Parts which are relatively small

2. Why use 3D printing?

It is crucial to consider the number of parts the mold is going to use. The materials provide extremely good wear resistance to repeated injection, closing and opening of the mold along with the temperature gradients. These were exposed to during the process of injection moulding.

For low-run molding, the wear resistance is not the most critical factor. Certain technologies of 3D printing such as SLA and Material Jetting are capable of producing parts of high accuracy having an excellent surface finish. This is further coupled with the modern temperature that is resistant to 3D printing materials. 3D printed molds allow quick verification of mold design and mitigate the financial risk of investing in an expensive metal mold.

3. Conclusion

High stiffness, high level of detail and high-temperature resistance is all that is required to create injection mold from 3D printing. Thus, the use of 3D printing in injection moulding is highly important. Make use of the best cheap injection moulding services.

Helpful Resources:

1. 16 Best (free) AMP – (Accelerated Mobile Pages) WordPress Plugins

2. 16 Best Free SEO WordPress plugins for your Blogs & websites

3. Riverdale Cast List For The TV Show Riverdale

4. Top 25 Best SolarMovie Alternatives

5. Top 5 Best Web Development Frameworks For Popular Programming Languages

AI Tools

How to Learn New Technologies and Tools More Easily

If you apply these strategies consistently, and maintain a healthy, adaptive mindset, you should have no trouble learning the new technologies and tools that become relevant to you.

In your personal and professional lives, you’ll occasionally run into new technologies and tools that have the potential to make your life easier but can also be very hard to learn. Learning how to operate machines safely and effectively can be a challenge, so how do you make it easier for yourself?

1. The Value of Learning New Technologies and Tools

There are several reasons why you might be interested in learning new technologies and tools. For most people, the primary motivation is developing or improving a set of skills that will be valuable in their jobs or careers. For example, if you become aerial lift certified online, you’ll gain the knowledge and experience necessary to safely operate certain types of lifting machinery, like aerial lifts, scissor lifts, and cherry pickers. This can make you more valuable to employers, give you more responsibilities, and help you make more money.

You may also be obligated to learn new technologies for your job. For example, if your employer rolls out a new ERP software system, you’ll likely need to learn how to incorporate it into your job seamlessly, with or without direct internal training.

Of course, some people simply like the process of learning new things or feel pressure to continuously adapt to a society that’s rapidly advancing. If you’re like most older adults, even the latest iteration of smartphone technology can feel a bit intimidating when you first get your hands on it, and it’s fun to gradually gain mastery over it.

2. How to Learn New Technologies and Tools More Easily

These are some strategies that can help you learn new technologies and tools much more easily:

Analyze your current position.

Before you start the learning process formally, it’s a good idea to analyze your current position. How much do you know about the tool in question? How competent do you feel navigating other tools and technologies? Are there any similar tools or technologies that you’ve learned in the past? How prepared do you feel for the learning process? Take note of your strengths and weaknesses and devise a strategy unique to you to overcome your personal challenges.

Process your anxiety and apprehension.

Anxiety and apprehension are common when learning new things. Even if these feelings are relatively minor for you, it’s a good idea to proactively address them and try to process them. These are normal and nothing to be concerned about, so confront them proactively.

Allow yourself time.

You might be a slow learner, or you might be a fast learner. Either way, it’s a good idea to give yourself as much time as possible to learn something new. If you force yourself to learn in very small time intervals, or if you try to learn everything the night before you’re responsible for knowing it, you’ll add undue pressure and make the environment much more stressful for you. Err on the side of caution and schedule yourself more time than you think you’ll need.

Identify and learn any important prerequisites.

Figure out if there are any prerequisites that are necessary or helpful for learning this technology or tool. For example, if you’re studying for a CDL license, it’s probably helpful to know the basics of driving first. This is another reason why it’s important to give yourself more time than you think you need; it might take you some time to learn baseline skills as building blocks for more advanced ones.

Look for educational resources.

For any tool or technology you can conceive of, there is probably an abundance of educational resources available to you. Formal training and certification programs, private coaching, video tutorials, and even educational podcasts can all play a role in shaping your knowledge and development.

Most people benefit from consulting multiple different educational resource types, so they can get information from multiple sources in multiple different ways. At the very least, you should identify one strong educational resource that can help you from start to finish.

Understand your own learning style.

Do you know your own learning style? For example, some people prefer learning visually, while others prefer a more hands-on approach. If you know your personal learning style, you’ll be able to chart a course for your own learning that caters to your natural strengths and inclinations.

Get help from someone experienced.

If you start struggling, try to get help from someone more experienced than you. Depending on the context of your learning, that could be a coworker, a mentor, a teacher, or even just a friend. Chances are, they’ll be more than likely to help you out.

Test your knowledge and practice.

At a certain point, you’ll have to stop learning and start doing. Be willing to test your knowledge and practice with the tool or technology you’re trying to learn.

Share with others.

You can reinforce the lessons you’ve already learned and engage with the material more strongly if you share your knowledge with others. It’s also a valuable opportunity to get more practice.

It doesn’t matter if you’re a slow learner. It doesn’t matter if you’re hesitant or even skeptical about new technologies. If you apply these strategies consistently, and maintain a healthy, adaptive mindset, you should have no trouble learning the new technologies and tools that become relevant to you.

-

Instagram4 years ago

Instagram4 years agoBuy IG likes and buy organic Instagram followers: where to buy them and how?

-

Instagram4 years ago

Instagram4 years ago100% Genuine Instagram Followers & Likes with Guaranteed Tool

-

Business5 years ago

Business5 years ago7 Must Have Digital Marketing Tools For Your Small Businesses

-

Instagram4 years ago

Instagram4 years agoInstagram Followers And Likes – Online Social Media Platform