Technology

Why Smart Tech Needs Smarter Building Blocks

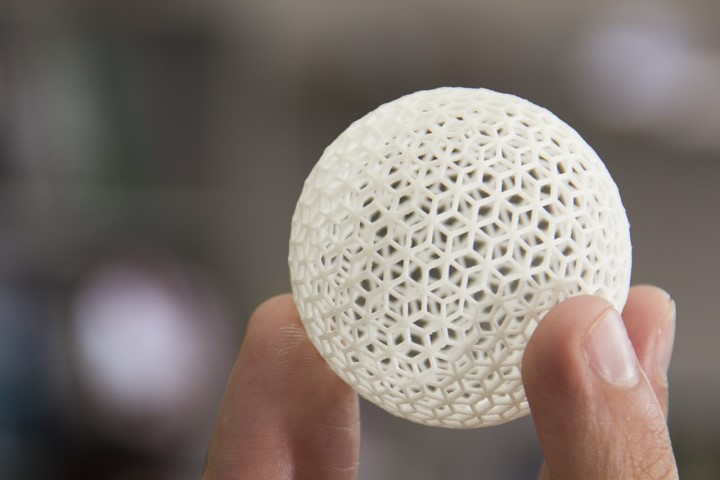

Smart devices, whether sensors, wearables, IoT gadgets, or advanced robotics, are rapidly transforming industries and everyday life.

Smart devices, whether sensors, wearables, IoT gadgets, or advanced robotics, are rapidly transforming industries and everyday life. But behind this surge sits an often-overlooked factor: materials. As we demand lighter, better-performing, and more sustainable technologies, we require smarter building blocks—innovative materials that deliver on these needs.

Table of Contents

1. Performance Requirements Are Escalating

Smart tech puts unique stresses on materials. Small form factors must now integrate high-speed electronics, tiny power sources, and durable enclosures. Materials have to be

- High-performance: capable of withstanding heat, friction, and wear

- Lightweight yet strong: supporting miniaturization without sacrificing durability

- Functional: enabling embedded antennas, capacitive touch, or self-healing surfaces

Traditional polymers like ABS or PVC often fall short. That’s why advanced polymers, from high-performance thermoplastics to specialty elastomers, are essential in next-gen devices.

2. Sustainability Is Non-Negotiable

Smart gadgets aren’t always built to last, yet they’re built to evolve. With frequent upgrades, recycling-friendly materials become critical. This drives demand for

- Biodegradable or bio-based polymers

- Recyclable composites that preserve performance across lifecycles

- Low-embodied-energy production methods

Polymer innovation supports closed-loop design, where electronics and materials are equally recyclable, reducing waste and environmental impact.

3. Functional Integration Is Key

Smart devices do more than compute—they sense, connect, and act. That demands materials capable of

- Embedding sensors or conductive pathways

- Protecting components while maintaining transparency or flexibility

- Achieving multi-functionality in a single component

Example: Smartwatch bands that monitor biometric data, requiring elastic polymers that are also hypoallergenic and skin-friendly. Another: housings that integrate RFID or NFC antennas, needing plastics with precise dielectric properties.

4. Challenges of Miniaturization

Today’s devices shrink yet grow in capability. Miniaturization forces materials to meet tighter tolerances, demanding

- Dimensional stability under thermal and mechanical stress

- Compatibility with micro-injection molding or high-precision CNC

- Surface finishes acceptable for electronics and optics

Meeting these criteria requires advanced polymer grades with consistent performance and reliable manufacturing characteristics.

5. Durability in Real-World Conditions

Your smart tech needs to work everywhere—on mountain peaks, in kitchens, under rain, and in dusty factories. That means materials must resist:

- Water, oils, dust, and UV light

- Mechanical impacts or repeated use

- Chemical exposure, like cleaning agents or sweat

Smart polymer formulations, including UV-stabilized, flame-retardant, or chemical-resistant options, help products survive real-world conditions.

6. Rapid Innovation & Time-to-Market

IoT and smart tech move at lightning speed. Short development cycles demand materials that:

- Have documented processing parameters (e.g., melt index, shrinkage, cycle times)

- Are available in multiple supply regions

- Work with different manufacturing processes

Off-the-shelf advanced polymers reduce design iteration time and enable faster prototyping and production.

7. Collaboration with Polymer Experts

To meet all these needs, tech companies increasingly partner with materials specialists. For example, a leading polymer company known for customizable formulations, tight processing control, and global supply can co-develop compounds tailor-made for smart tech applications.

Their expertise helps optimize:

- Resin blends for conductivity or flexibility

- Additives for flame resistance or UV stability

- Physical performance (impact strength, fatigue resistance)

This partnership allows seamless translation of material specs into manufacturing results.

8. Case Study: Smart Medical Wearables

Medical-grade wearables demand lightweight, skin-safe housings with embedded electrodes. Engineers might specify:

- TPU blends that resist sweat and sanitize easily

- Low-shrinkage masterbatches to maintain a tight fit with electronics

- Conductive pathways built into the polymer matrix

Polymer experts can tune the formulation for compliance with medical regulations, manufacturability, and wearer comfort—a true synergy of smart tech and smarter building blocks.

9. Looking Ahead: Adaptive & Programmable Materials

Future smart materials might actively respond to environments—self-healing plastics that mend scratches or piezoelectric composites that harvest energy. But these require deep material-science know-how. Advances in polymer chemistry, processing, and nanotechnology can unlock these capabilities, paving the way for genuinely intelligent devices.

Conclusion: Why Material Matters

Smart technology isn’t just about chips and code. It’s equally about the materials that make performance possible. Polymers form the backbone of device enclosures, sensors, cabling, and wearables. And as demands grow—for performance, sustainability, miniaturization, speed, and adaptability—only smarter building blocks will suffice.

For tech innovators, this means embracing advanced polymer partners and pursuing custom materials solutions. Smart tech needs smarter materials. And with the right pieces in place, the next generation of smart devices will be lighter, greener, and more capable than ever.

-

Instagram5 years ago

Instagram5 years agoBuy IG likes and buy organic Instagram followers: where to buy them and how?

-

Instagram5 years ago

Instagram5 years ago100% Genuine Instagram Followers & Likes with Guaranteed Tool

-

Business6 years ago

Business6 years ago7 Must Have Digital Marketing Tools For Your Small Businesses

-

Instagram5 years ago

Instagram5 years agoInstagram Followers And Likes – Online Social Media Platform